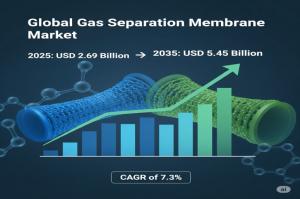

Gas Separation Membranes Market Drive Decarbonization & Efficiency, Market to Hit USD 5.45 Billion by 2035 at 7.3% CAGR

Japan’s membrane separation market is set to grow from USD 0.28B in 2025 to USD 0.50B by 2035, driven by hydrogen goals, CO₂ capture, and METI’s green funding.

NEWARK, DE, UNITED STATES, August 6, 2025 /EINPresswire.com/ -- As global industries face the dual challenge of decarbonization and operational efficiency, the gas separation membrane market emerges as a pivotal enabler, set to grow from USD 2.69 billion in 2025 to USD 5.45 billion by 2035, achieving a robust CAGR of 7.3%. With strong policy backing, technological innovation, and shifting industrial priorities, membrane systems are fast becoming the backbone of next-generation gas processing platforms.

At the heart of this transformation is the urgent demand for energy-efficient, modular, and compact separation technologies, which are redefining traditional workflows across hydrogen recovery, carbon dioxide separation, and nitrogen generation. Manufacturers striving to meet tightening regulatory standards while maintaining profitability are increasingly investing in membrane-based solutions to future-proof their operations.

Membranes Over Machinery: A New Industrial Paradigm

Government mandates and shifting economics are accelerating the adoption of gas separation membranes over conventional systems like cryogenic distillation and pressure swing adsorption. The European Commission’s 2025 Energy Transition Directive, for instance, is reshaping gas processing standards by mandating membrane-based CO₂ separation in key industries by 2030. The USA Department of Energy is similarly investing in pilot programs to deploy membrane-based carbon capture, citing their low operational overhead and high scalability.

For manufacturers, these shifts present a vital opportunity: to modernize operations without the heavy footprint or energy demand of legacy systems.

Next-Generation Polymers: The Backbone of Future Growth

Advanced polymeric membranes—particularly polyimide and polysulfone variants—are poised to dominate the market, growing from USD 1.94 billion in 2025 to USD 4.21 billion by 2035. These materials offer enhanced chemical and thermal stability, essential for rugged environments such as oil & gas, refineries, and chemical processing.

Complementing these are mixed-matrix membranes embedded with MOFs and zeolites, which enhance selectivity and lifespan. From nanocomposites that boost thermal resistance to MOF-integrated membranes capable of handling complex feeds, polymer innovation is unlocking new frontiers of gas separation.

Technology in Sync: AI, Automation, and Predictive Maintenance

The gas separation membrane market is not just a materials story—it’s a technology revolution. Industry leaders are embedding AI, IoT, and automation into every stage of design and deployment:

• Air Liquide uses digital twin platforms to predict membrane wear and optimize replacement cycles.

• Linde and Air Products leverage real-time analytics and sensor-enabled systems to enhance purity control in hydrogen and nitrogen processing.

• MTR is streamlining production with robotic sealing systems, while Pall Corporation employs machine learning to engineer ultra-thin, selective membranes.

This tech-driven transformation is crucial for manufacturers targeting lower OPEX, higher throughput, and predictive maintenance. Modular by Design: Hollow Fiber Takes the Lead

From small-scale biogas facilities to sprawling petrochemical complexes, modular design is a defining strength of modern membrane systems. Hollow fiber modules are leading the pack, expected to grow from USD 1.62 billion to USD 3.47 billion by 2035, thanks to their high surface-area-to-volume ratio and compact footprint.

These systems are proving especially effective in:

• Hydrogen purification in refineries

• Carbon dioxide removal in natural gas processing

• Nitrogen generation for inerting systems

By reducing space, weight, and installation time, these modules give manufacturers the flexibility to expand or retrofit operations with minimal disruption.

Carbon Capture, Hydrogen Purification, and Beyond

By application, carbon dioxide separation leads market growth with a CAGR of 8.3%, driven by industrial decarbonization and biogas upgrading. Hydrogen separation, essential for the green transition, follows with a CAGR of 7.4%, as nations pursue clean hydrogen strategies.

These high-growth segments are opening doors for:

• Refineries recovering hydrogen from purge streams

• Biogas plants upgrading methane content

• Industrial clusters implementing carbon capture at scale

Membranes’ energy efficiency and ease of modularization give them a strategic edge in these emerging use cases.

Manufacturing Growth Engine: Industrial Uptake on the Rise

Industrial adoption is surging across oil & gas, chemicals, power, pharmaceuticals, and food & beverage. The oil & gas sector alone will double in value by 2035, from USD 1.01 billion to USD 2.08 billion, as operators replace bulky separation units with lightweight, modular membranes.

Key drivers include:

• Space constraints on offshore platforms

• VOC recovery and inert gas generation in chemical plants

• Nitrogen and CO₂ control in food packaging environments

For manufacturers seeking to enhance operational agility while meeting emissions targets, membrane systems deliver a compelling return on investment.

Request Gas Separation Membrane Market Draft Report:

https://www.futuremarketinsights.com/reports/sample/rep-gb-5513

For more on their methodology and market coverage, visit https://www.futuremarketinsights.com/about-us.

Global Momentum, Local Action

From China’s dual-carbon goals to India’s Green Hydrogen Mission, countries are moving fast to adopt membrane technologies. China’s CAGR of 8.2% and India’s 7.8% highlight the region’s role as both a manufacturing hub and innovation hotspot. Meanwhile, Japan, Germany, and the United States are anchoring growth with strong R&D and pilot deployments.

Top companies like Air Products, Honeywell, Air Liquide, MTR, and UBE Industries are dominating through integrated platforms, global service footprints, and domain-specific expertise.

Related Insights from Future Market Insights (FMI)

Gas Convection Oven Market - https://www.futuremarketinsights.com/reports/gas-convection-oven-market

Gas Insulated Power Equipment Market - https://www.futuremarketinsights.com/reports/gas-insulated-power-equipment-market

Gastric Space-Occupying Devices Market - https://www.futuremarketinsights.com/reports/gastric-space-occupying-devices-market

Gas Fired Chemical Boiler Market - https://www.futuremarketinsights.com/reports/gas-fired-chemical-boiler-market

Gas Pipeline Infrastructure Market - https://www.futuremarketinsights.com/reports/gas-pipeline-infrastructure-market

Editor’s Note:

The Gas Separation Membrane Market is witnessing significant momentum driven by energy efficiency, sustainability, and industrial demand for CO₂ and hydrogen recovery. As industries shift towards cleaner technologies, these membranes are becoming integral to future-ready operations. Stay tuned for deeper insights into key trends and growth dynamics shaping this evolving market.

Rahul Singh

Future Market Insights Inc.

+1 347-918-3531

email us here

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.